Braided structures

Braiding of carbon composites is made in two way: biaxial and triaxial. The parameters of biaxially braided yarn as crossing fibers, their orientation, strength and yield of braiding. These variations are repeated and can be foreseen which allows precise manufacture of composite parts. Carbon fibers are stranding at +- 45 degrees angle.

Triaxial knit has between the two sets of fibers the third set woven in the direction of the axis of the tube or tape. This will both increase density and strength of result item.

Properties of composites are highly dependent on the direction and angle of twisting. Physical properties can be very effective influencing by changing the proportion of carbon and glass fibers in a snarl. In addition can be influencing too with the amount of reinforcing component (epoxy resin) - max. amount is 80%.

Basic informations about braiding you can found here.

Shapes of composites

By default, the fibers of the knitting machine, weaving together a "stock", which has a very flexible form with the possibility of adjusting it according to your requirements. The mandrel is braided in yarn that eventually forms a solid knitwear, which is reinforced with other fibers in the longitudinal axis. This unique triaxes knit greatly increases the stiffness and bending properties of composites. Once saturated with epoxy resin, item is removed form the core and the resulting product is cured in an autoclave.

We can produce any profile of the composite, according to the customer's wish. Write us, certainly we can find a suitable solution for you!

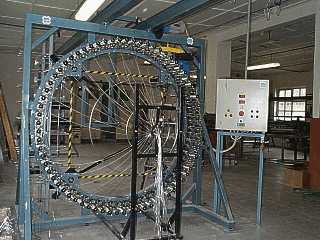

One of Technofiber's braiding machines