Production of carbon composites

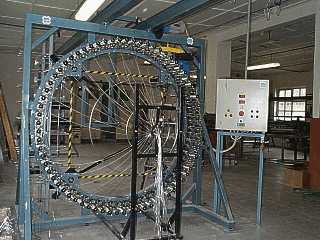

Triaxial braid gives a final product unsurpassed strength and rigidity and a high degree of resistance to breakage or other damage. Compact uninterrupted structure "sock" made up of interlocking carbon fibers with a defined stiffness and high resistance guarantees homogeneity of the material. All threads are woven in shape for the resulting product. This leads to the optimal distribution of the individual fibers with the management of their density and direction.

The product is usually made up of several layers, which are gradually saturate by mixture of epoxy resin and hardener. This procedure optimize amount of resin in the resulting composite. Glass liner in the last layer delivers surface properties, especially hardness of the resulting product. After a defined number of braided layers, products are steeped in a special curing chamber at a temperature higher than 160° C.

Compared with composite products manufactured from prepreg (semi-woven carbon fiber in a semi state in a mixture of epoxy resin and hardener), our products are in many respects qualitatively superior.

Our products are virtually indestructible - those that break is probably broken due to mishandling.

Relatively complex triaxial technology is replaced by different manufacturers with taping machine technology, which provides visually nearly comparable products. But greater resistance to impact of knitted composites is unmatched (up to 10 times higher) and in particular their structural integrity is maintained even after further technological processing (eg. drilling).

Braiding on the flexible core and subsequent creeping of products in negative forms allows us to produce complex shapes and features, while maintaining all the technological advantages of braided structures.

We are constantly working on develop and improve our processes and products. We believe that our products will become the foundation of all sports equipment and complex industrial facilities. We are aware that it is not qualified to cover all possibilities of composite materials. A significant portion of our products is therefore provided in collaboration with specialized manufacturers, using their knowledge and experience and then becomes the basis for their production.

Our philosophy is very simple: Satisfied customers come back to us for other products and recommend our products to others.